Description

Description

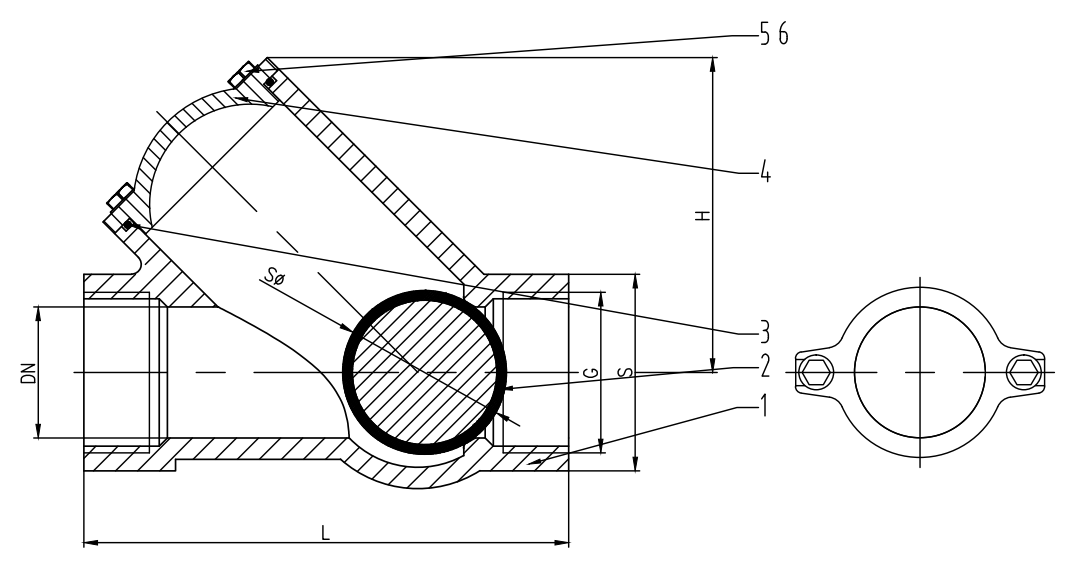

Ball check valves contain a ball that sits on the seat, which has only one through-hole. The ball has a slightly larger diameter than that of the through-hole (seat). When the pressure behind the seat exceeds that above the ball, liquid is allowed to flow through the valve. But once the pressure above the ball exceeds the pressure below the seat, the ball returns to rest in the seat, forming a seal that prevents backflow. The ball moves up and down inside the valve depending on the flow and seals against the machined seat when no flow or reverse flow occurs and seals against the seat to stop the reverse flow. Ball check valves are typically preferred for use in pumping stations as they are self-cleaning as the ball rotates during the operation and are vertically maintenance-free. IVALVE offers both flange and thread connections for the Ball Check Valves.

Standard and Features

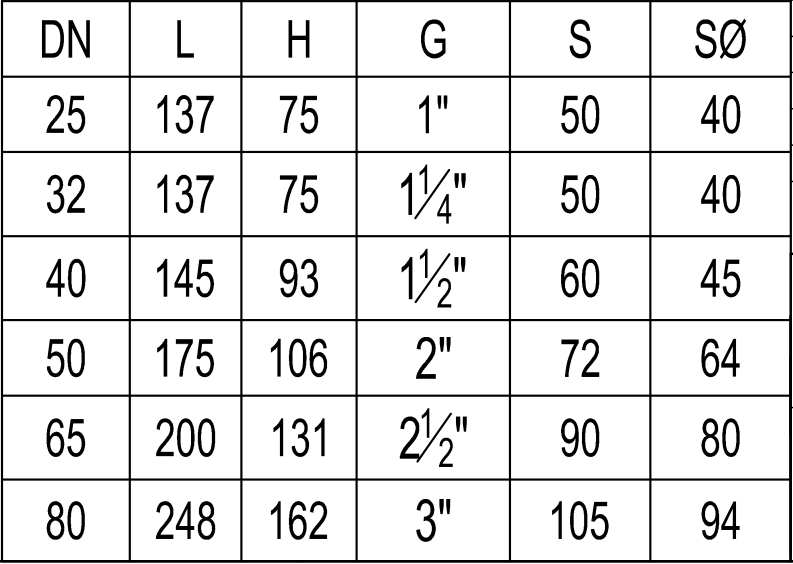

Size range: threaded end DN25-80

Face to face: DIN3202-F6

Hydraulic pressure test : Seal: 1.1 x PN (in bar), Body: 1.5 x PN (in bar)

Coating: Fusion bonded epoxy coating,Color upon request

WRAS certified for drinking water

Medium: Neutral water, Drinking water, Sewage

Temperature Range: 0℃ - 80℃

100% testing before packing and delivery

Technical Data

Copyright © IVALVE TECH. (TONGLING) CO.,LTD. All rights reserved.