Description

Silent check valves, also known as non-slam check valves and spring-assisted check valves reduce or eliminate water hammer and its effects.

Water hammer refers to the high-pressure shock waves that occur when the flow of fluid abruptly stops (due to pump shut down or a valve disc quickly closing) in a piping system. When water hammer occurs, the resulting flow reversal places severe stress on the pipe, endangering its structural integrity, and opening it to potential rupture and damage.

To control water hammer and reverse flow, the use of silent check valves is recommended. When the source moving the fluid shuts down and the forward flow of the fluid decreases, the specially designed stainless steel spring action of the silent check valve controls the valve disc closure to occur prior to flow reversal. This spring assist insures that the valve does not slam shut, and the occurrence of water hammer is eliminated.

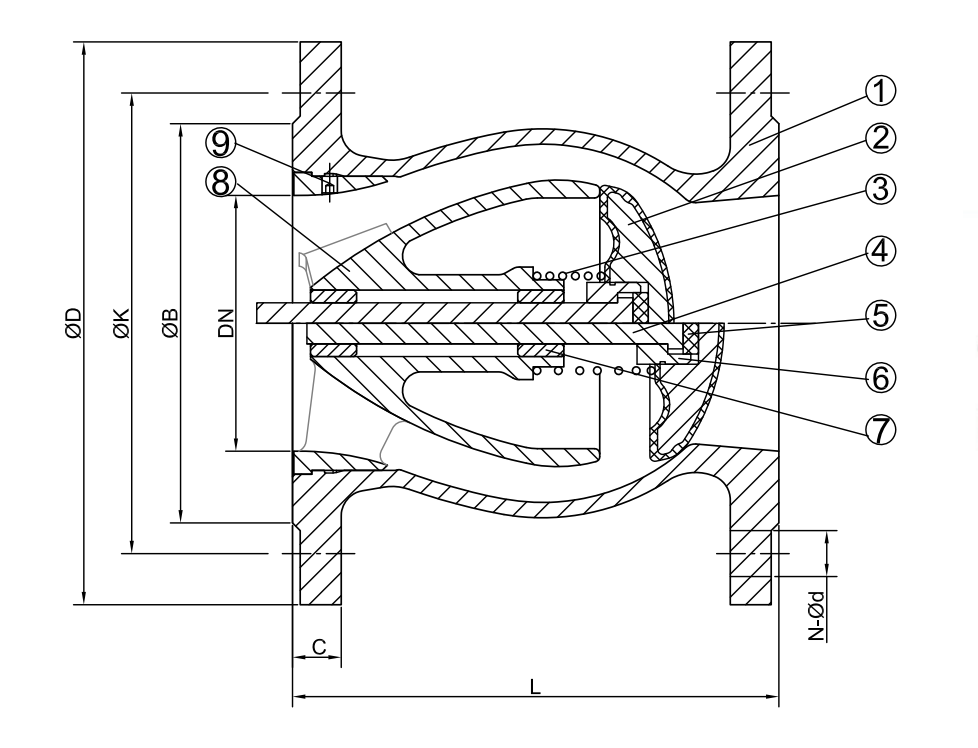

| Design | GB/T 12235-2007 |

|||

| Flange | EN 1092-2 | |||

| Face to Face |

EN 558-1 | |||

| Tests | EN12266 |

|||

| Operation | Self-motion |

|||

| Medium | Water |

|||

| Temperature | 0-80℃ |

|||

| Seal Test | 11/18/28Bar | |||

| Body Test | 15/24/38Bar |

|||

| PN | 10/16/25Bar | |||

| DN | DN50-DN350 | |||

Features:

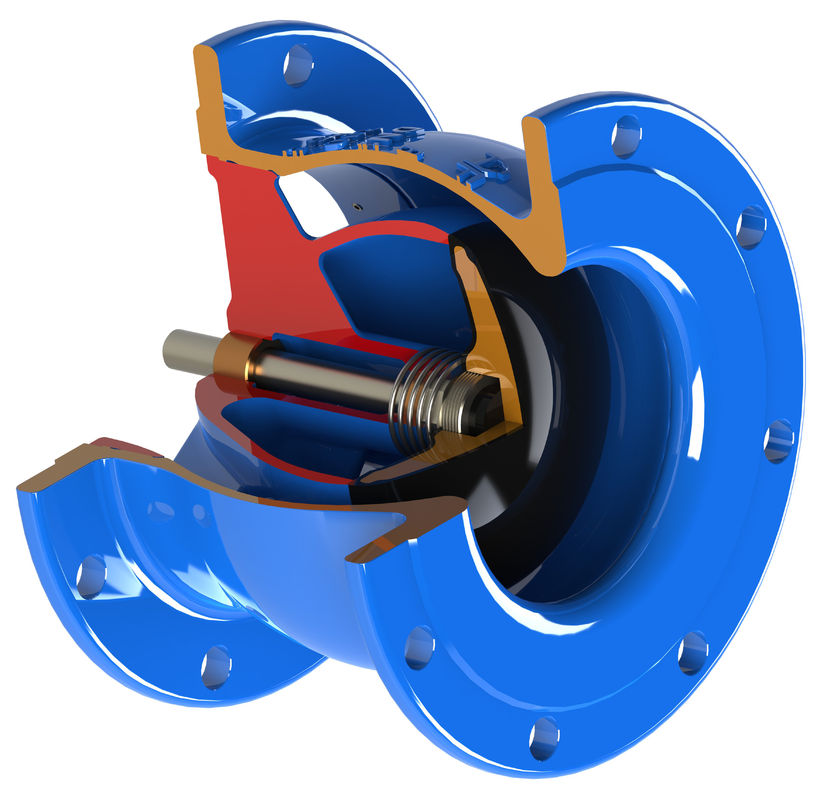

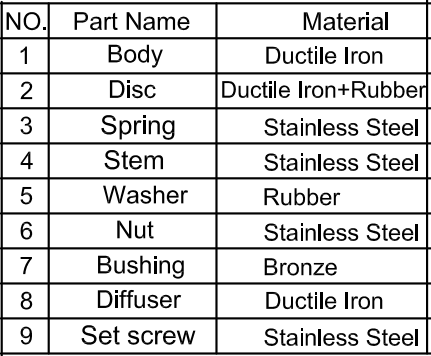

· High strength ductile iron body used for durability and less weight.

· Advanced dynamic design of single body with diffuser provides streamline flow and assures lower head loss.

· One of the lowest head loss check valve, big save in pumping power cost, valve disc with shorter stroker and spring reverse faster than most of check valve.

· Coated with powder epoxy both inside & outside for corrosion resistance.

· Bronze bushing reduce wearing problem during operation.

· Hydrodynamic design with spring ensures non slamming and water hammerless.

· Stainless steel spring hidden in the diffuser under protection while valve in operation.

· Disc will positively close before reverse flow, and maximize the closing speed up to 0.2 Sec.

· Installation can be vertical/horizontal/ inclined.

· Comply with EN 558-1, ISO 5752 and EN 1092-2, ISO 7005-2 flange dimension.

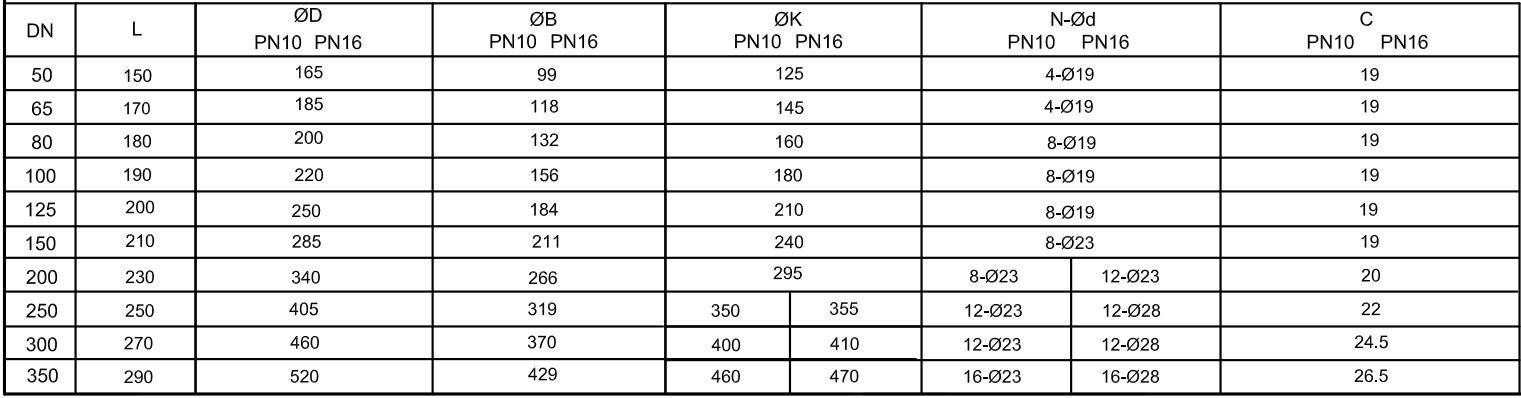

Technical Data

铜陵爱阀科技有限公司 版权所有